g503.com GPW Judging Standard

WIKI-ENGINE

Back to the Ford GPW

Judging Standard Index Page!

3.0.1 Engine block

3.0.1 Engine block

The engine block is finished in a medium gray gloss enamel.

Two colors of gray were used during GPW production. The earlier

color is a cold slate-gray while the later color is lighter and warmer.The date

of the color change is not known at this time.

Cast markings: GPW 6015 in raised letters on lower-right side of

block, with a script “f” above.

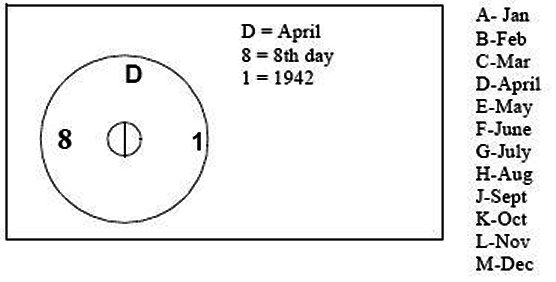

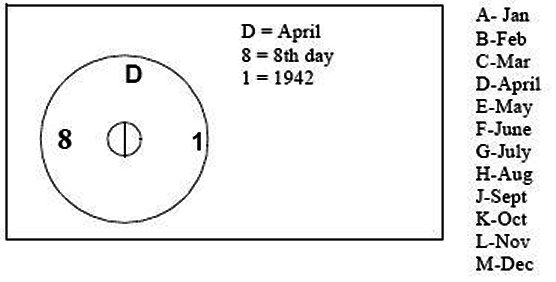

Early engines had a

casting date code located on the lower rear corner of the right side of the

block. This code included a single letter representing the month (i.e. A =

January) and the numeric representation of the

day. An additional digit may have represented the mold pattern number.

Around August, 1943, engine casting dates were relocated on the

block. These date codes were located below the distributor and started with a

letter representing the month followed by the day and the last digit of the

year. For example H3311 was cast on August 3, 1943. The final two digits

may indicate the mold or line number.

The serial number pad, located behind the oil filter is stamped

with the engine serial number. The engines were stamped with their serial number

when the blocks were machined, and the chassis were stamped with the engine’s

serial number at the time the engine was mated to the frame. As a result,

occasionally GPWs would roll off the assembly lines with a serial number that

would appear to belong to a much older vehicle.

Around 12/42, the block casting or machining process was

changed, resulting in a change to the serial number pad. At this point, the pad

was no longer machined uniformly smooth from front to rear, but incorporated a

“step” at the very rear of the pad.

Engines numbered 232051 through 243405 use studs NOT bolts to

retain the valve covers. Use of bolts in these blocks will crack the cylinder

wall bosses. Also, all spare engines with casting dates of K-10-4 to L-29-4 were

changed to studs.*

The engine serial number should match chassis and data plate

numbers. Non-matching serial numbers will result in a significant deduction of

judging points.

* Per J.Gilmore archival research (!FoMoCo 12/44)

Updates to this info below this line

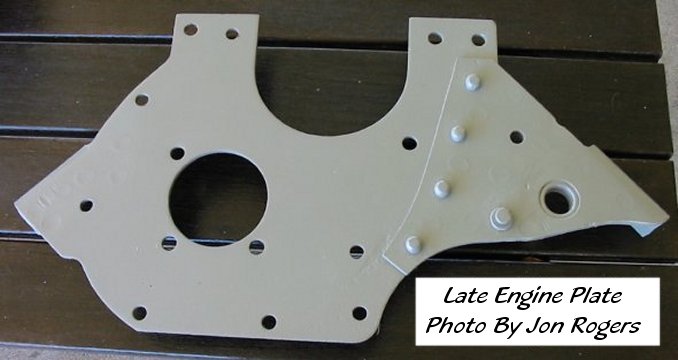

3.0.2 Engine front mounting plate

3.0.2 Engine front mounting plate

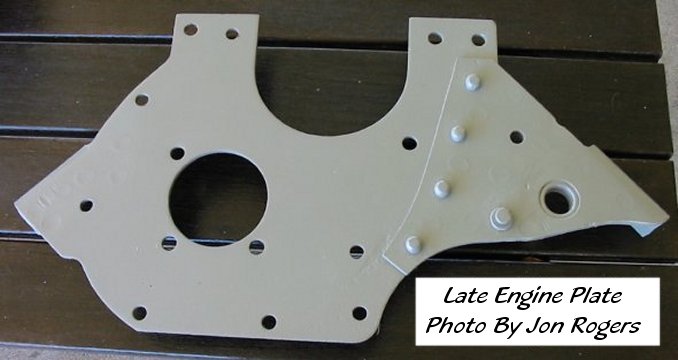

The engine front mounting plate was changed sometime in early 1943* with the

addition of a reinforcing plate on the generator side. This reinforcement was

attached with ***three (3) rivets near the timing chain cover.

*“Ordinance Dept. report” described in AAW VII states that change was made

1/16/43.

Updates to this info below this line

***Looking at several Front Plates, I think the CORRECT number of rivets for the

reinforced LATE-style is FOUR, not the THREE as shown in the printed version of

the Judging Standard above.

Chuck Lutz

3.0.3 Valve cover and crankcase ventilation

3.0.3 Valve cover and crankcase ventilation

The early road-draft crankcase vent system was used from start of production

thru February, 1943. After this, positive crankcase ventilation was introduced,

which resulted in changes to the oil filler tube, carburetor to air cleaner

crossover tube, intake manifold and the addition of a PCV valve and plumbing.

Updates to this info below this line

3.0.4 Cylinder head

3.0.4 Cylinder head

Cylinder head markings include script “f” and 6050 near oil

filter bracket.

The cylinder head is attached with 9 “f” Head bolts and 6 studs. The

studs have a visible dome end and are painted along with the block. The head

stud nuts, are heavy dimension and are S7 finished.

The center rear stud is longer then the rest, to accommodate the cylinder

head to firewall ground strap. A second nut, along with two flat washers and a

lock washer retain the cylinder head side of the strap.

The thermostat housing is marked GPW 8250 with a script “f”

Updates to this info below this line

The attaching of the cylinder head was all studs after

GPW 242992 - Jon Rogers

3.0.5 Oil pan and oil filler

3.0.5 Oil pan and oil filler

Vehicles produced before a certain date in 1942 included an early style oil

pan which used a cast drain boss, attached to the pan with three rivets and

sealed with solder*. The oil pan is fastened to the engine block with recessed

hex head integral-lockwasher bolts. The crankshaft pulley shield is fastened to

the timing chain cover with four recessed hex head lockwasher bolts that also

hold the front of the oil pan. Spacer rings are used between the shield and the

pan to prevent interference. The threaded ends of the bolts should not extend

too far past the timing cover flange. The pulley shield is properly marked with

a script “f”.

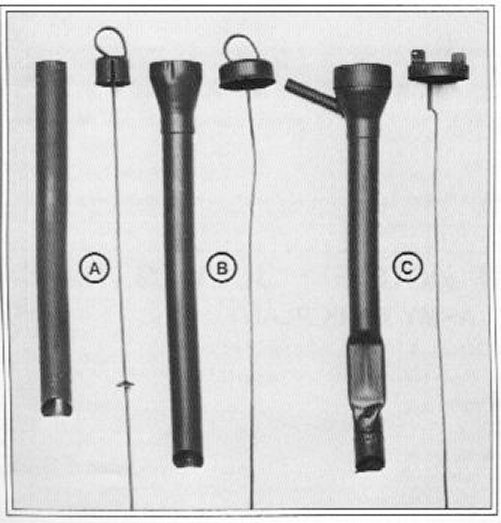

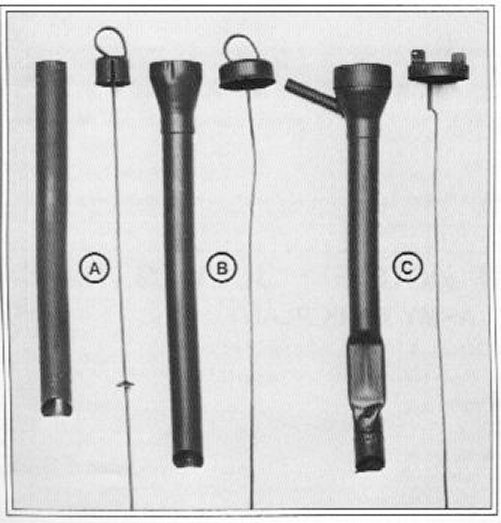

Three styles of oil filler tube and dipstick were used during GPW production:

A) The Very Early style (PN GPW-6763A) with narrow cap was used from start of

production thru March ‘42. B) The Early style (GPW-6763B) with friction-fit

funnel top was used from April ‘42 thru Dec ‘42. C) The late style (GPW-6763C)

with crankcase vent and bayonet cap was introduced Feb. 8th 1943 and was used

thru the end of production. **

The oil pump is marked GPW 6604 with a script “f”

* Have been unable to find any reference to change in oil pan. Date should

be determined based on documentation or observation. ** Changeover

date courtesy Jim Gilmore based on Ford archival research.

Updates to this info below this line

Part number for early style dipstick(B) should be GPW-6766B.(from NOS

dipstick with Ford tag attached) -Todd Haley

3.0.6 Manifolds

3.0.6 Manifolds

Markings: Exhaust GPW 9430 f , intake GPW 9425

f

PCV was introduced in February 1943* at which time the intake manifold was

drilled and tapped for vent lines. Before February 1943 the intake manifold was

not drilled and no bosses were present.

* “Willys-Ford teardown report” AAW#2, p213 states that Nov’42 GPW did not

have tapped manifold.

Updates to this info below this line

3.0.7 Carburetor

3.0.7 Carburetor

The correct GPW carburetor is a Carter model 539S also known as type W-O. The

carburetor bowl, cover and horn are natural finished cast zinc (not gold).

The cast iron carburetor base is not drilled and tapped for a pipe plug as

are the later civilian carburetor bases. The base is finished with a black

chemical treatment similar to S2, it is dead flat with a white or gray tinge.The

throttle shaft lever, throttle arm, rod, choke link, choke lever and all

hardware are cad plated. The metering control rod is retained at the throttle

arm with a bayonet-type washer and spring which is usually missing or replaced

with an incorrect substitute. Most carb parts are marked with a Carter “C” logo

and the Carter part number.

The carburetor is mounted to the intake manifold with two 3/8” hex jam (thin)

nuts and split lockwashers, all S2 finished.

The carburetor linkage is painted gray with the exception of the return

spring which is S2 finished.

Updates to this info below this line

3.0.8 Oil filter and bracket

3.0.8 Oil filter and bracket

For most of production, the standard GPW oil filter was a purolator cartridge

type. Certain units may have utilized a Fram filter assembly after mid 1943.

The Purolator filter is identifiable by its dome shaped cover, marked

COVER ASSEMBLY 25791 PUROLATOR PRODUCTS INC MILITARY STANDARD

FILTER There are three decals on the filter assembly, a cover decal

describing servicing procedures, a body decal with a script “f” and the

part number “GPW 18660” and one marked PUROLATOR PRODUCTS INC

CASE ASSEMBLY-26708 USE JUNIOR ELEMENT. The decal background is properly

a deep red color as compared to the incorrect orange decals commonly available

today. The oil filter body is stamped INLET in 1/4” block letters in

silver paint above the inlet port. The body, cover and cover bolt of the

Purolator filter are painted an eggshell finish black enamel. Oil filter bands

are made of 1/8”x7/8” steel, slotted mounting holes have rounded ends. Bands,

screws and square nuts are painted black.

Flex oil lines are lacquered cotton braid cover (not rubber).

The oil filter bracket is painted gray engine color. The filter assembly is

attached to the oil filter bracket with S7 or S2* finished bolt, lock washer and

flat washer.

* Both S7 and S2 hardware appear in factory photographs.

Updates to this info below this line

Note figure 2(page 11) and figure 3(page12) of the judging guide show a FRAM

oil filter.

3.0.9 Water pump, Fan & fan belt

3.0.9 Water pump, Fan & fan belt

The fan is finished in semi-gloss black enamel and is attached to the

waterpump pulley with four S2 hex screws and split lockwashers. The water pump

is marked with a script f

Various types of Ford marked fan belts were used including one with the part

number GPW-8620 & S-2673 embossed on the belt in raised letters as well as

GPW-8620-A2 or GPW-8620-3 stenciled on the belt.

Updates to this info below this line

On later Water pumps, recessed hex head bolts were used. NOS Ford engine

photo below.

This Web Page Created with PageBreeze Free HTML

Editor